Identify equipment from inspection photo and append inspection conclusion to database

Photo of a motor taken during routine inspection, matched against maintenance history database, and addition of latest inspection to history database.

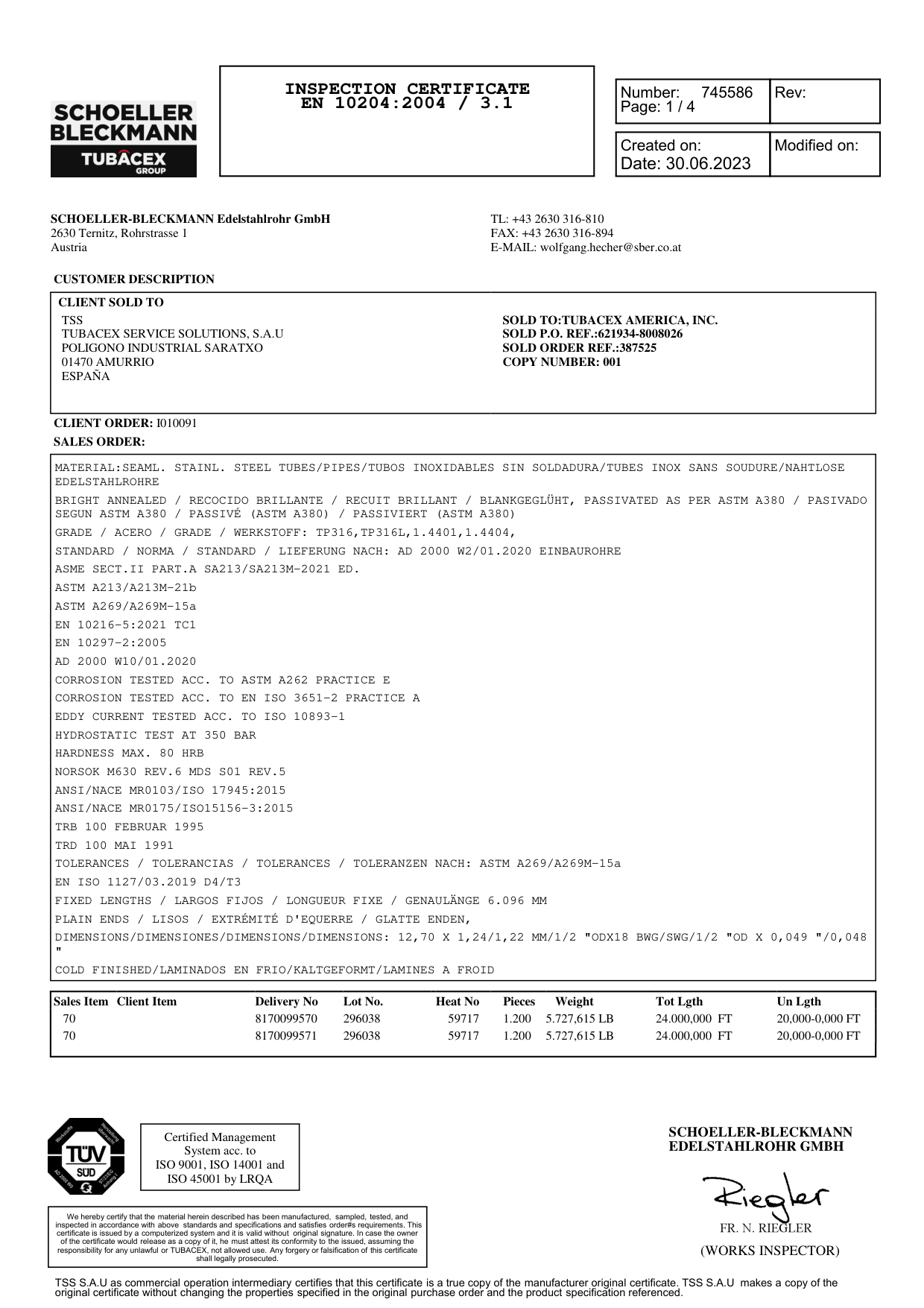

We extracted:

- Manufacturer

- Type

- P/N

- Serial number

We found:

- Serial number

- Inspection history

We derived:

- Condition trend

- Next inspection date

- Findings

- Proposed action

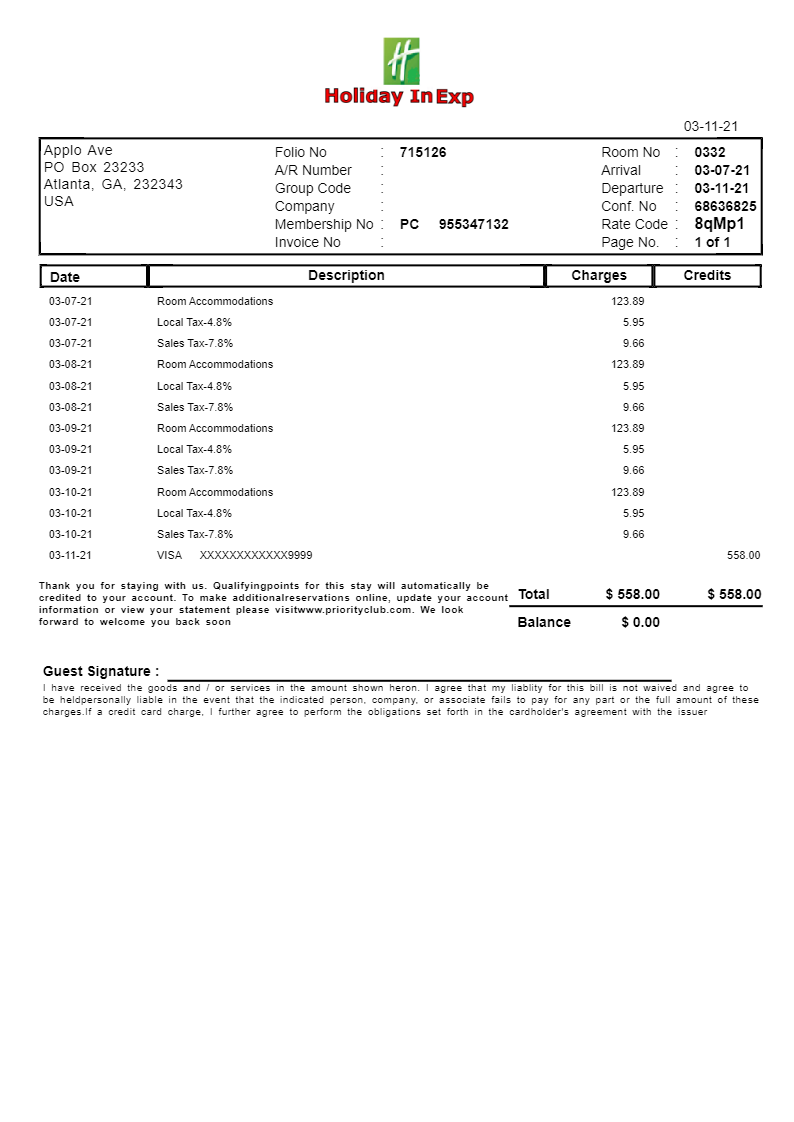

Output preview:

Updated inspection database:

| Serial | Date | Inspector | Condition | Findings | Action | Status |

|---|---|---|---|---|---|---|

| 0016093703 | 2026-01-27 | L. Dubois | Fair | Dust buildup, exposed wiring | Clean and re-insulate within 60 days | Open |

| 0016093703 | 2025-07-14 | J. Peeters | Good | Minor dust | Clean during next service | Closed |

| 0016093703 | 2025-01-20 | M. Claes | Good | None | No action needed | Closed |

| 0016093703 | 2024-07-15 | J. Peeters | Good | None | No action needed | Closed |